The complete line of

valve

manufacturer and

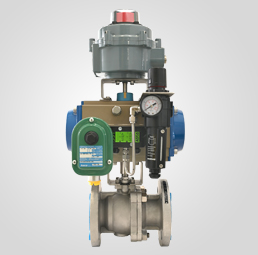

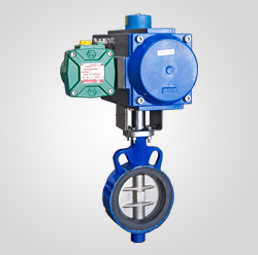

automated valves

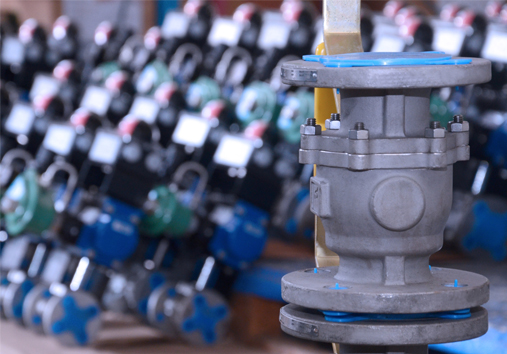

Unlocking excellence, IPC is a leading valve manufacturer that delivers a comprehensive array of Valves including Gate, Globe, Check and Ball Valves. IPC also offers Automated Valves, Limit Switch boxes and Pneumatic Actuators. Our profound process expertise sets us distinctly ahead in the Industry.

Product Range

Features that distinguish us

-

Range

Range -

Technology

Technology -

Customisation

Customisation -

Certification

Certification

The Comprehensive range

Your trusted source for a comprehensive range of valve manufacturer with high-quality GGC Valves, Ball Valves, Automated Valves and valve accessories like Limit Switch Boxes and Actuators. With a commitment to excellence and customer satisfaction, we deliver reliable solutions to meet the diverse needs of industrial sectors.

Stat-of-the-art Technology

Harnessing cutting-edge technology to engineer reliable and efficient GGC valve solutions for today’s industrial needs. Our dedication to innovation ensures that we stay ahead of the curve, delivering advanced valve systems that optimize performance and enhance productivity.

Meeting your specific needs

With customization as our expertise, we tailor valve solutions to meet your specific requirements. Our team of experts excels in delivering custom solutions, ensuring that our valves integrate seamlessly into your industrial processes.

Meeting the global standards

Numbers Speak

Numbers Speak

Numbers Speak

900+

Happy Customers

120+

Industry Experts

20+

Years' Experience

12+

Sectors Served

Industries we serve

Power

Empower your Power Sector Operations with IPC Valves!

Oil and Gas

Assured reliability required in Oil and Gas!

Boiler & Steam Application

Your partner in Boiler & Steam Application Manufacturing Excellence!

Fertilizers

Supercharge your Fertilizer Manufacturing: unlock success with IPC Valves!

Chemicals

Valves for Chemicals Production process

Paints and Dyes

Unleash Vibrant Potential with IPC Valves!‘

Pharmaceuticals

Specialized valves for Pharmaceuticals!

Effluent Treatment Plants

Your partner in sector Effluent Treatment Plants (ETPs)!

Key Approvals

At a glance