The wall holds off the sea, providing isolation to the island, and making it habitable. If the wall is breached, the island will be flooded in no time.

Isolation valves are the walls that are holding off certain media from a particular process.

Isolation valves completely stop the flow of material into a specific area of the plant. Isolation valves are used to stop or divert the material to a chosen location for critical actions such as:

- Enable maintenance works

- Allow removal and replacement of equipment

- Facilitate a safe shut down of plants during emergencies.

Right isolation practices are critical

Engineering a dike according to the height of land and flow of the water is what makes it effective against possible floods. In the case of your in-plant dikes i.e isolation valves, the right isolation configuration is the key to shutting off a particular area or process.

Are your isolation valves rightly configured?

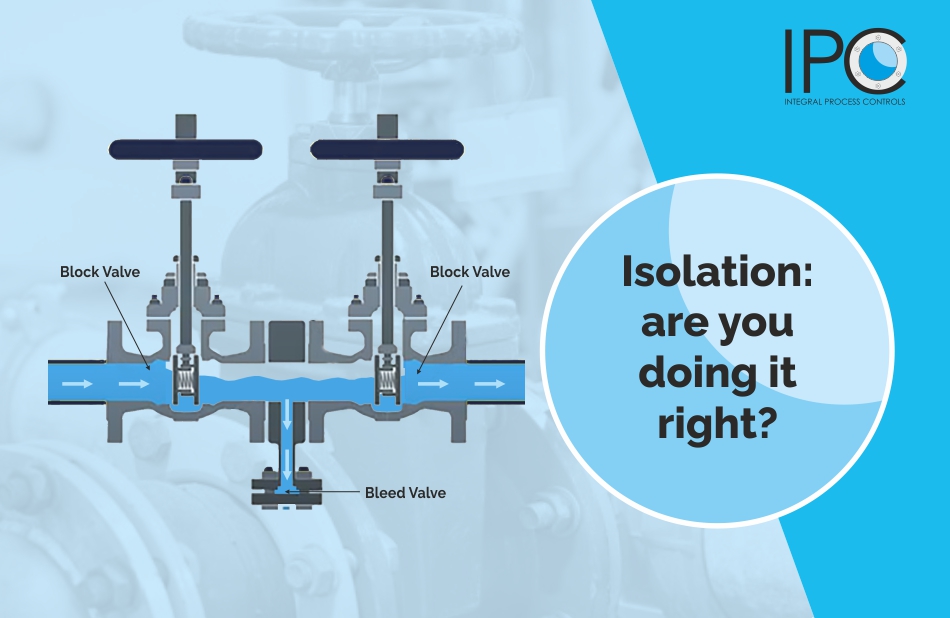

There exist 3 major valve systems for effective isolation.

Two valves are provided on the upstream as well as the downstream side of the pipe to block the material flow on both sides. Gate, ball, needle, or globe valves could be used as blocking valves. Next, a third valve is inserted in the center cavity of the two-block valves. This is the bleed valve that drains the material away from the intermediate space between the two valves.

A double block and bleed system can comprise of three separate valves, or a specially designed single unit DBB valve which can save a lot of space and costs.

A double block and bleed system is suitable for isolation as well as calibration and venting purposes.

Gauge root valves are valves with a single inlet and three outlets. In some cases, two of its outlets are plugged and a gauge is connected to the third port to provide for a more convenient orientation of the connected handle or gauge. Gauge root valves can also enable a wide range of applications by enabling the connection of additional instruments.

Single block and bleed valves are used to isolate flow in one direction during maintenance works. These valves are generally used for non-critical and non-toxic applications. In this configuration, the block valve is closed first, after which, the shutdown side of the block and bleed assembly is drained to carry out maintenance.

Gate, globe, or ball valves are most commonly used as isolation valves.

Factors to consider when choosing isolation valves

- The valves chosen must be designed to provide a positive shutoff seal to ensure pressure retention.

- Valves specified for control or throttling purposes should not be used for isolation

- If actuated valves are used, the actuator mechanism must be isolated from all possible supply sources before the start of work.

Conclusion

If a crucial island is to be habitable and safe from the sea, the dikes around it must be strong and well-engineered. Isolation valves are the walls that are critical to the safety and successful maintenance of a control network. Factors such as the type of process media, as well as its temperature and flow rate impact the selection of isolation valves. Safety is the key purpose of these valves. In that light, the use of a single closed valve for isolation carries a risk factor. It is possible for a person to mistakenly open the closed valve, or, the valve might have leaks. The type of valves should also be closely considered. Note that check valves, control valves, and relief valves are not suitable for isolation purposes.

If you have additional queries about any aspect of valve maintenance, use, and manufacturing, drops us a mail at evalve@ipcvalves.com.