Cracking pressure makes as critical a difference to check valve performance as the valve’s material composition.

What is cracking pressure?

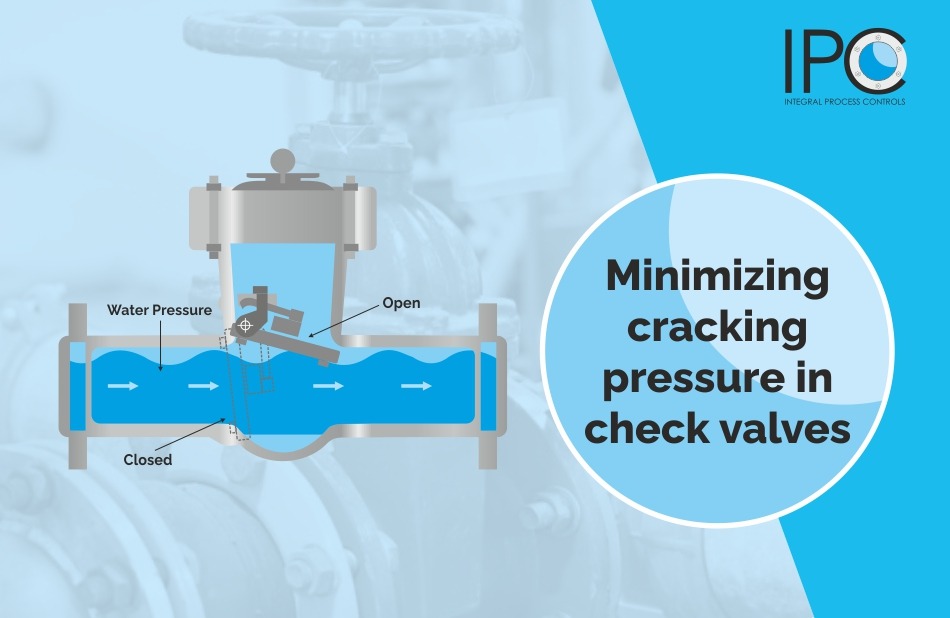

Check valves are designed to allow the flow of media in a single direction. They open using the upstream pressure of the flowing media. Cracking pressure is the point at which the valve opens sufficiently to allow a detectable flow of the media.

Even an ounce of imbalance in cracking pressure can deeply impact valve performance

Cracking pressure affects the valve’s sealing performance. The amount of backflow pressure needed to close the check valve is called resealing pressure. Check valves with a lower cracking pressure need a higher reseal pressure to stay closed. If the reseal pressure is not adequate, fluid media can bleed backwards, which is dangerous for certain applications.

If the cracking pressure is too high, the valve may open less than needed, or not at all. When the valve isn’t fully open, it could lead to chatter, or pop, causing premature wear and tear of the valve’s internal parts.

Factors impacting cracking pressure of check valves

Valve size: Cracking pressure issues are generally faced in valves of a smaller size. The bigger the valve, the lesser the cracking pressure.

Spring strength: The spring attached to the valve disc helps provide some force and set a specific cracking pressure for the valve.

Service conditions: Harsh service conditions can result in damage such as wear of the seat, fatigue on the spring, deterioration of elastomers, and other issues. This reduces the performance of the valve.

Media properties: The pressure and temperature of the media impact both the cracking pressure and reseal pressure of the valve. At IPC, we closely study your application requirements to design, manufacture and supply customized valves in the shortest possible lead time. The ideal cracking pressure in valves should be around 1.5 bar. At IPC we maintain the cracking pressure at around 0.5 bar for the best results. The number may vary as per the needs of your application.

Ensuring the correct cracking pressure for check valves.

Inadequate cracking pressure could lead to leakage and contamination within the valve. Hence, proper sealing and adequate reseal pressure should be the key pointer when looking at valve cracking pressure. A valve that has a slightly higher cracking pressure, but offers reliable shut-off in the reverse direction would be a good choice.