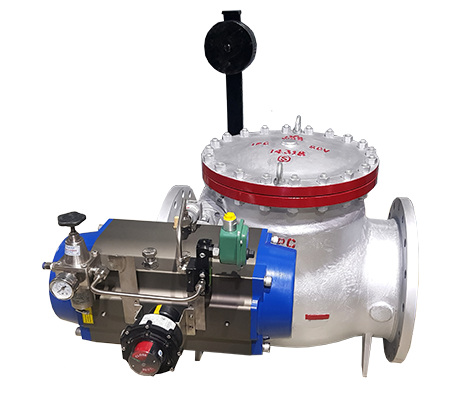

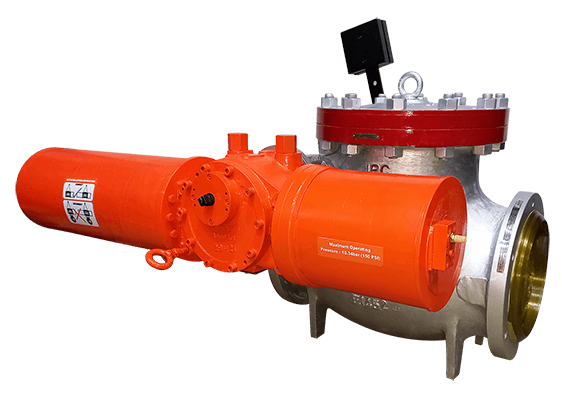

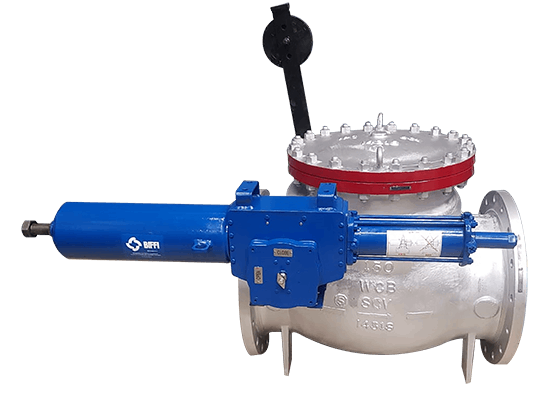

Quick Closing Non-return Valve

Specialised valves for turbine applications

Quick closing non-return valves mainly used in the turbine extraction pipelines that supply steam to the primary-secondary heater, auxiliary turbines and other equipment. They prevent reversal of flow and provide shut off, thus limiting the damage to the source equipment in the event of a trip.

The main function is the quick shut Off of the bleeding steam pipes, in case of loss of turbine load, to prevent the dangerous water carryover from the preheater back to the turbine.

Benefits

Protects sophisticated systems & equipment from damage

Compact actuator for reduced footprint

Reduced pressure loss

Specifications

Pressure rating 150 through 2500

Sizes 4" TO 24" (DN-100 TO DN-600)

Mfg. standards API 594 / BS 1868 / ASME B16.34

Flange details STD AS PER ASME B16.5; OTHERS AS PER BS, AWWA, EN, DIN

End to end dimensions AS PER ASME B16.10

Testing standards API 598 / BS EN 12266-Part 1 & Part 2

Buttweld end details AS PER ASME B16.25

Features

Protects sophisticated systems & equipment from damage

Compact actuator for reduced footprint

Reduced pressure loss

Certifications

Valves Approvals

Downloads

Frequently Asked Questions

It is a specialized safety sentry for steam pipelines. It’s a type of check valve with one critical job: to slam shut incredibly fast the instant it detects a reverse flow, isolating sections of a system to prevent catastrophic damage.

Speed is everything for protection. In critical systems like turbine extraction lines, a sudden pressure drop or reverse flow can happen in milliseconds. A standard check valve might close too slowly, allowing dangerous backflow. The quick-closing mechanism acts as a fail-safe to limit damage in the event of a system trip or failure.

They are specialist components mainly used in turbine extraction pipelines in power generation and other heavy industries. They are installed on lines that supply steam to equipment like feedwater heaters and auxiliary turbines.

Its main function is quick shut-off. For example, if a turbine suddenly loses load, these valves instantly close the “bleeding” steam pipes. This prevents a dangerous reversal where condensed water from a preheater could be carried back into the hot turbine, which could cause severe mechanical damage.

Be prepared to discuss the specific application (e.g., turbine extraction line, pump discharge), the pipeline size, pressure/temperature ratings, and the required speed of closure. This information is crucial for our engineers to recommend the correct design.

IPC specializes in engineering valves for critical safety and process applications. Our Quick Closing Non-return Valves are built with the robustness and reliability needed to protect expensive and essential equipment like turbines, giving you confidence in your system’s integrity.